On the eve of the Inventor and Innovator Day the employees whose ideas and proposals had been successfully put into practice in production or will be implemented in the nearest future were honoured at the Arkhangelsk Pulp and Paper Mill.

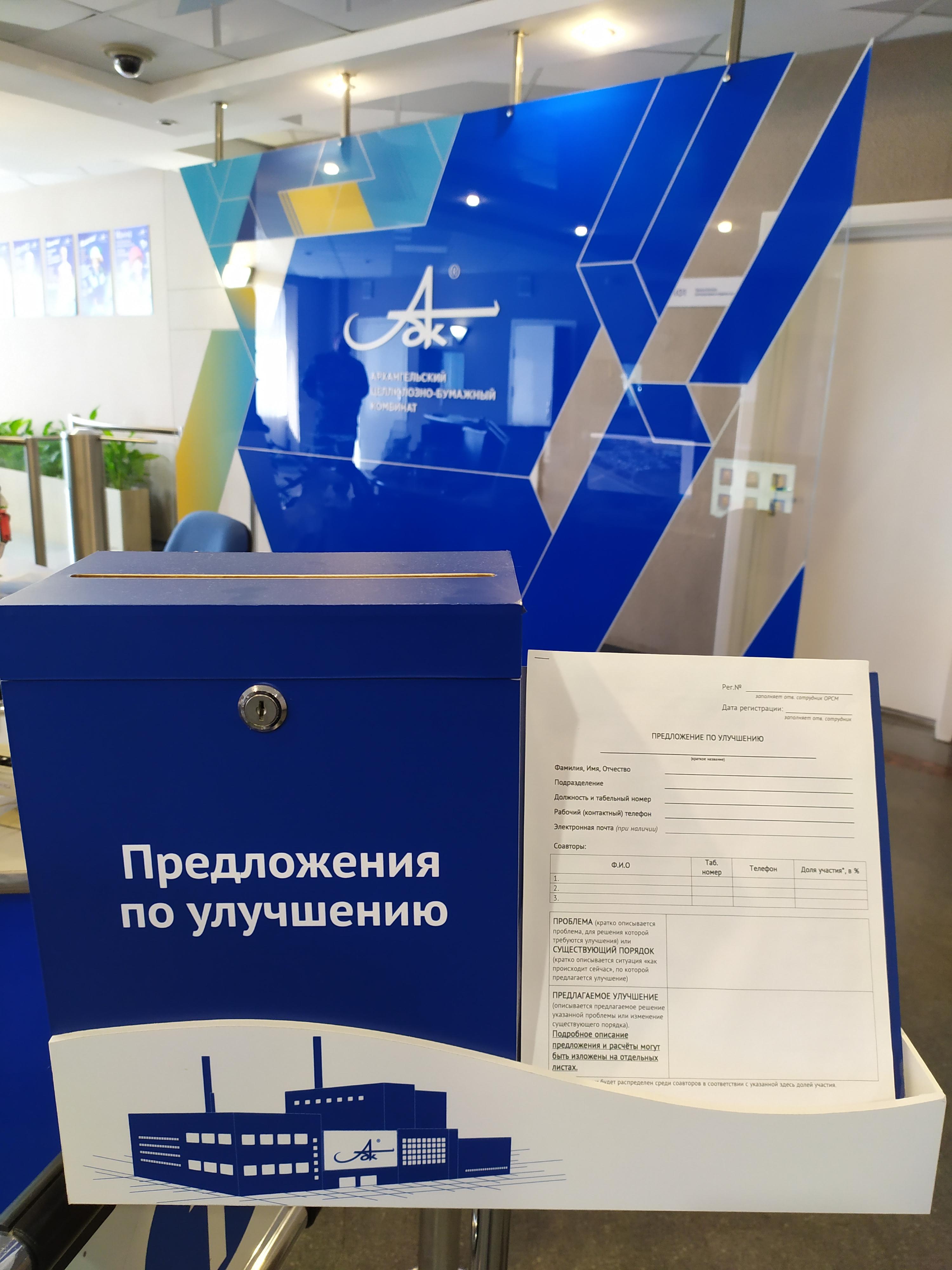

The innovation incentive system has been operating at the plant since 2018. Everyone who wishes can make a proposal of a technical or organizational nature. The main criterion is the benefit for the employees or for the enterprise.

The author receives monetary bonus for the implemented proposal. If it is possible to calculate the economic effect of the idea, the author receives a bonus in the amount of 10% of the total amount of the funds saved during the year, and, what is more, the maximum payout amount may reach 1 million roubles! If the economic effect cannot be calculated, the amount of the bonus is determined by the expert board. In this case monetary bonus may reach 200 thousand roubles.

– Even in Soviet times the innovation movement was actively developing. We continue this good tradition, noted Dmitry Zyliov, Director General of the Arkhangelsk Pulp and Paper Mill JSC at the official awarding ceremony in the honour of the authors of the best ideas. – The APPM is a huge and very complicated mechanism, where every process is important. If desired, anyone can make a contribution to the plant development. The main thing here is the sense of personal involvement in common cause. It is very pleasant that every year the number of useful proposals increases.

8 employees of the plant were awarded according to the results of the year.

Dmitry Kasimov, head of the evaporator section of TPP-2 has developed a scheme for separating reagent supply for water treatment at the evaporation station. Now the reagent is supplied to the common line for three boilers at once. The separate reagent supply will allow to significantly increase the boilers service life.

The head of section of pulp and paper production shop Andrey Grebenev and the leading mechanic of pulp production Pavel Kukin have improved the system for felt tracing and conditioning on paper machine №6.

– Our proposal for changing felt tracing and its diminishing without affecting the PM performance will give a pronounced economic effect, increase the operational properties of the felt and reduce the cost of the product, Andrey Grebenev said. – We are very pleased that our project has been appreciated. We have many more ideas.

At the initiative of Alexander Sosnin, head of the wood preparation shop №4 a fence not provided by design has been installed in the dangerous areas in the shop. As a result, the safety level for the shop personnel has been significantly raised. And together with Igor Sergeyev, the leading mechanic of the wood-exchange production, Alexander Sosnin organized the replacement of vertical ladders with flight stairs, which made the work in the workshop not only safer but more convenient as well.

Larisa Karmakulova, leading specialist of the Department for Efficient Production, suggested providing the key specialists of the APPM with helmets of different colours so that during the period of repair works contractors employees could easily find the shift foreman. This solution will allow to save working time on searching for specialists at an unfamiliar production site.

Nina Yelagina, specialist of the Department for Efficient Production, developed a memory leaflet containing the necessary information and contact data of technical services for contractors employees which also greatly facilitates the work of third-party specialists.

Yana Shevchuk, engineer, developed the environmental logo of the APPM which was first used at the 1st Research-to-Practice conference “Environmental Aspects of Modern Technologies in the Timber-Chemical complex”.

Other authors of the projects approved by the experts were also rewarded. Among the awarded innovators a prize drawing was held, among the prizes there was a sports bicycle, a Yandex station, a smartphone and other valuable gifts.