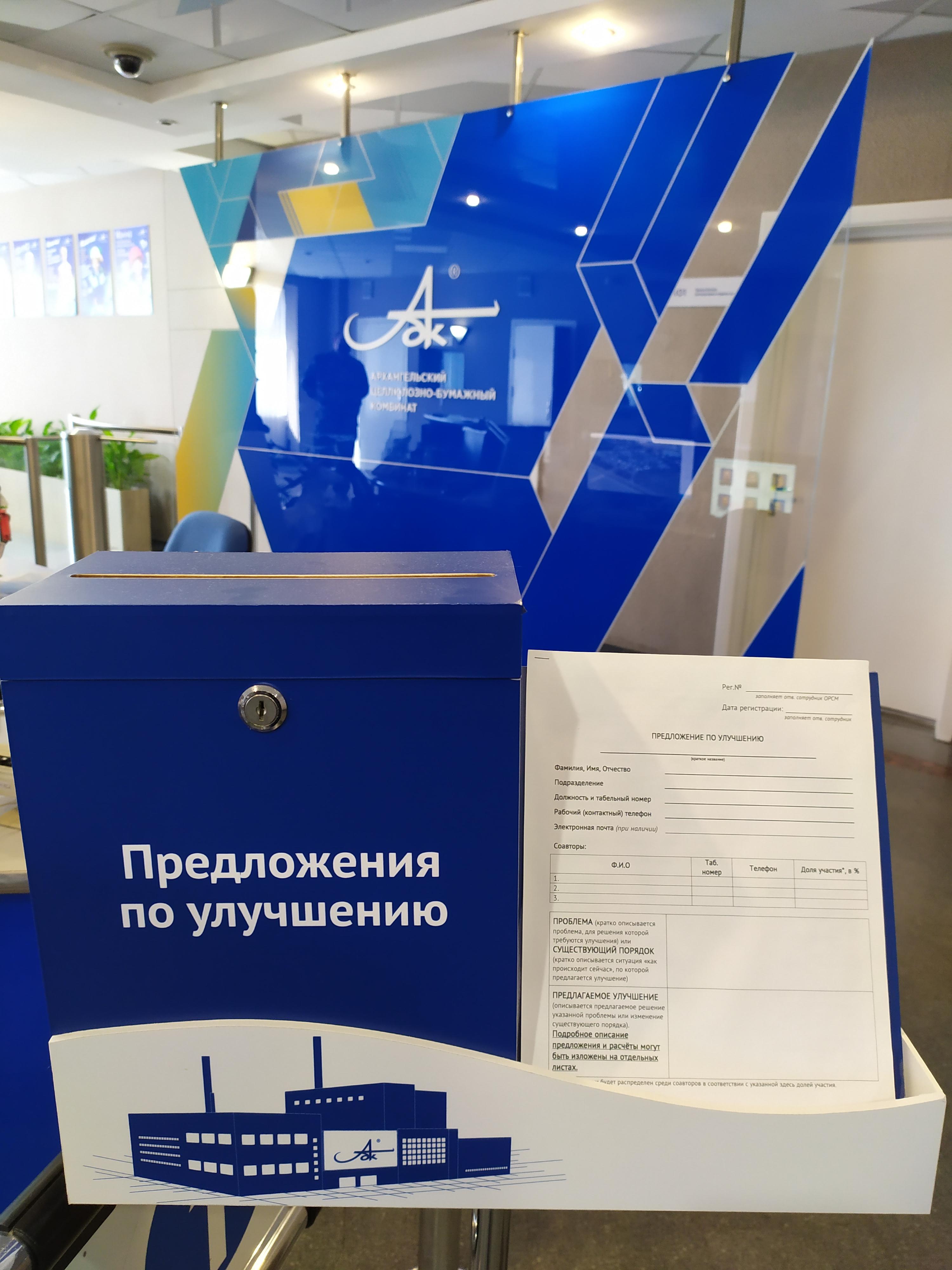

The development and implementation of innovations at the Arkhangelsk pulp and Paper Mill has been practised successfully for a long time. The management of the enterprise is interested in stimulating creative potential of its employees. The team regularly makes proposals.

– The innovation incentive system has been working at the plant since 2018. Every employee wishing to make a proposal of а technical or organizational nature may do it. The main criterion is the benefit for the employees and the enterprise as a whole, - said Alexey Gulin, Head of the Organizational Development Department of the Arkhangelsk Pulp and Paper Mill, JSC. – Moreover, the author receives monetary bonus for the implemented proposal. If it is possible to calculate the economic effect of the idea, the author receives a bonus in the amount of 10% of the total amount of the funds saved during the year, and, what is more, the maximum payout amount may reach 1 million rubles! And such bonuses were paid out at the APPM more than once. If the economic effect cannot be calculated, the amount of the bonus is determined by the expert board. In this case monetary bonus may reach 200 thousand rubles.

The regular review of the proposal applications took place in April. Of the 15 pre-approved innovations, the expert board selected 14.

For example, the specialists of the APPM Efficient Production Department developed a brochure for the contractors employees involved in equipment repairing. It is often difficult for contractors employees to orient themselves at the unfamiliar plant. Detailed information on the timing of temporary restrictions for work performance, contacts of technical services coordinating repairs, information on medical care and food service stations at the plant is given in the brochure.– The first experience showed that the innovation turned out to be very useful for our contractors. All the information necessary for working at the unfamiliar production site given in a separate memo saves time significantly and, what is important, allows to reduce unnecessary workers’ movement around the workshops, - said Vyacheslav Rusakov, Chief Engineer of the Arkhangelsk Pulp and Paper Mill, JSC. – Many initiatives make it possible to save resource consumption, but often there come in proposals the effect of the implementation of which can be felt far from immediately, the so-called delayed effect.

For instance, a proposal was approved to reduce water consumption in the production of cardboard. For waste dilution from vortex top ply and back ply stock cleaning the workshop employees suggested taking technical – tray water instead of using fresh water at board machine №1. Annual saving is to exceed 652 thousand cubic metres of fresh water. The project is planned to be implemented this year.

There have been also made proposals on increasing productivity of wood debarking, reducing of steam consumption in winter, reducing possible downtime of conveyor equipment, stabilization of balance supply in wood preparation shop №3 and a number of other proposals.

– The main thing here is the sense of personal involvement in common cause. The APPM is a huge and very complicated mechanism, where every process is important. If desired, anyone can make a contribution to the plant development. All the conditions for it have been created, - says Dmitry Zyliov, Director General of the Arkhangelsk Pulp and Paper Mill, JSC.

The employees who made the most interesting improving proposals will be separately marked by the Arkhangelsk Pulp and Paper Mill management on June,25 on the eve of the Inventor ant Innovator Day.