About Us

Arkhangelsk Pulp & Paper Mill is one of the leading timber and chemical companies in Russia and Eastern Europe. The Company manufactures cardboard, pulp, paper.

The Chief Executive Officer is

Zylev Dmitry Igorevich

1940

the Plant was established

1981

was rewarded with

the Order of Lenin

the Order of Lenin

The Company is recognized as a LEADER in the social and environmental policies

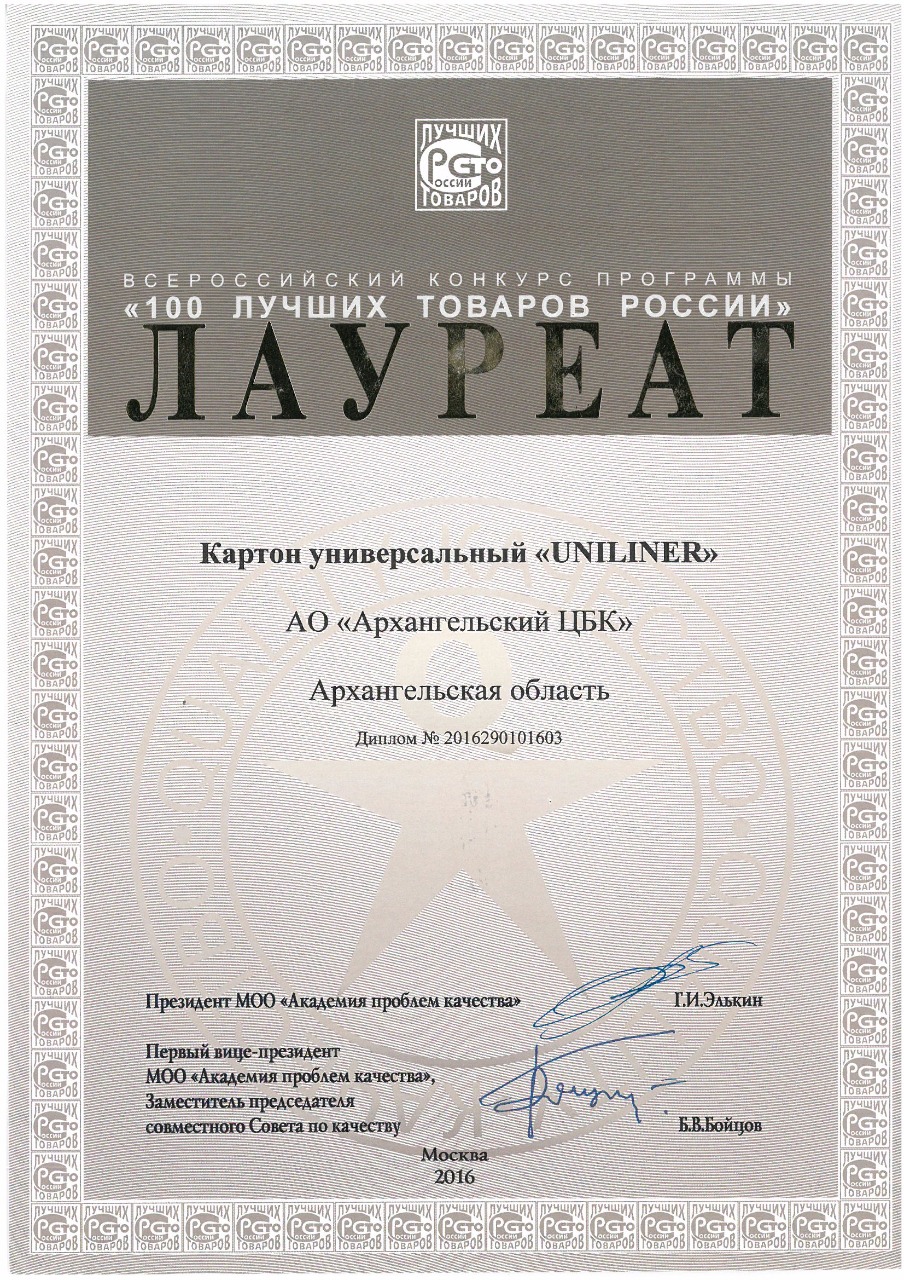

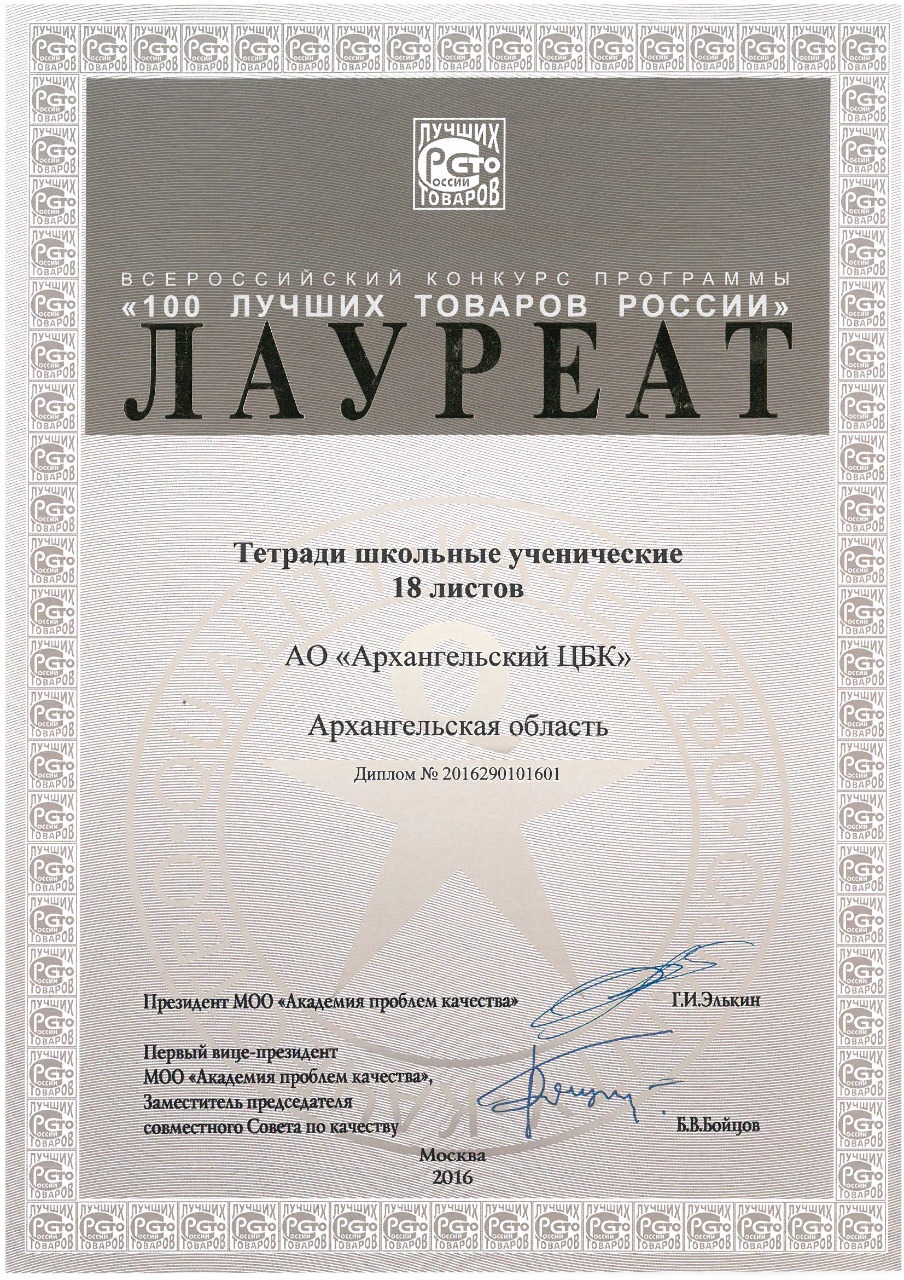

Company's products have won the "Russia's 100 Best Products" prizes

The Plant closely cooperates with the Northern Arctic Federal University, a partner of APPM in scientific research and development as well as in training of professional human resources.

As the backbone Plant of the city of Novodvinsk, Arkhangelsk PPM works closely with the city on major social issues.

History

The history of Arkhangelsk Pulp and Paper Mill is one of challenges, outstanding achievements and victories.

It projects the destiny of the whole country and its people. It is the history of the tens of thousands of people of Novodvinsk and Arkhangelsk, families and dynasties who made history with their own hands, their professionalism and hard work, and who well deserved the biggest reward of their era, the Order of Lenin, as the symbol of the highest possible recognition of the work accomplished by the entire team of the Plant.

It projects the destiny of the whole country and its people. It is the history of the tens of thousands of people of Novodvinsk and Arkhangelsk, families and dynasties who made history with their own hands, their professionalism and hard work, and who well deserved the biggest reward of their era, the Order of Lenin, as the symbol of the highest possible recognition of the work accomplished by the entire team of the Plant.

Key milestones in

the history of

Arkhangelsk PPM

the history of

The history of Arkhangelsk PPM

The history of Arkhangelsk Pulp and Paper Mill is one of challenges, outstanding achievements and victories. It projects the destiny of the whole country and its people.

It is the history of the tens of thousands of people of Novodvinsk and Arkhangelsk, families and dynasties who made history with their own hands, their professionalism and hard work, and who well deserved the biggest reward of their era, the Order of Lenin, as the symbol of the highest possible recognition of the work accomplished by the entire team of the Plant.

1940

the first mill production units were launched: nearly 100 tons of unbleached pulp and over 140 tons of wrapping paper produced by the end of the year

1945

bleached pulp production started

1960

paper production launched

1963

notebook production launched

1968

cardboard production launched

1975

pulp production started

1980

launch of hardwood pulp production

1981

Lenin Order award

1997

elemental-chlorine-free pulp produced

1998

the Mill's organization and management reform is started. APPM becomes Russia's best exporter of the year and is ranked among Russia's largest companies by sales

2001

SAP R/3 Integrated Management System is introduced.

2003

APPM becomes Russia's first timber industry company whose CO2 emission data is validated by international environmental organization

2006

FSC Chain of Custody Certification is secured. Arkhangelsk PPM is the first in Russia to produce FSC-certified pulp

2007

the new wood yard No.4 is launched with the innovative dry debarking process implemented

APPM opens NARFU's Pulp and Paper Production Process academic department

APPM opens NARFU's Pulp and Paper Production Process academic department

2013

Stage I of “the Cardboard Production Reconstruction” priority investment project (PIP) is launched at Arkhangelsk PPM.

2014

APPM secures Russia's first certification according to ISO 14064, Greenhouse gases.

CHP-1 starts up a new multi-fuel boiler co-fired with wastewater sludge and bark/wood waste, manufactured by Valmet Power Oy, which utilizes the innovative bubbling fluidized bed combustion technology (Hybex™...

CHP-1 starts up a new multi-fuel boiler co-fired with wastewater sludge and bark/wood waste, manufactured by Valmet Power Oy, which utilizes the innovative bubbling fluidized bed combustion technology (Hybex™...

2015

An innovative semichemical pulp plant is put into operation as part of PIP Stage I with a capacity of 1000 tons of the intermediate product per day.

The start of PIP Stage II for a complete process flow upgrade of Board Machine No.2 and construction of a new evaporation plant.

APPM bec...

The start of PIP Stage II for a complete process flow upgrade of Board Machine No.2 and construction of a new evaporation plant.

APPM bec...

Mission and Strategy

Our mission

The Company's mission is to operate efficiently in order to ensure maximum profit for the shareholders and make a strong contribution to the region and country's economy, and be responsible toward the Company's personnel and the public.

Our strategy

Our strategy is to ensure the sustainable development of the Company in order to:

- improve the Company's profitability and its shareholder value

- improve the quality and competitive capacity of the Company's products

- enhance the environmental safety of the operations and minimize negative impact on the environment

- further develop the vertically integrated business system

Starting from 2000, we have been implementing a large-scale modernization program aimed to improve the quality of products and minimize the environmental impact. The Company has prepared and approved its development strategy until 2025, which clearly defines the goals and objectives for key business operations of the Plant.

Strategy-2025 goals:

2025

+15%

Production growth (in terms of cooking volume) from 870 to >1000 k tons per year

+25%

Growth of cardboard and fluting output

100%

Complete transition from coal to gas and renewable energy sources

≥20%

Increase in the share of high conversion products in the Group

Ecological effect*:

50%

Reduction of water consumption

65%

Reduction of pollutants

emission

emission

75%

Reduction of water pollutants disposal

18 k tons

Reduction of greenhouse gas emissions, CO₂ equivalent (1%)

* - with increase of production output

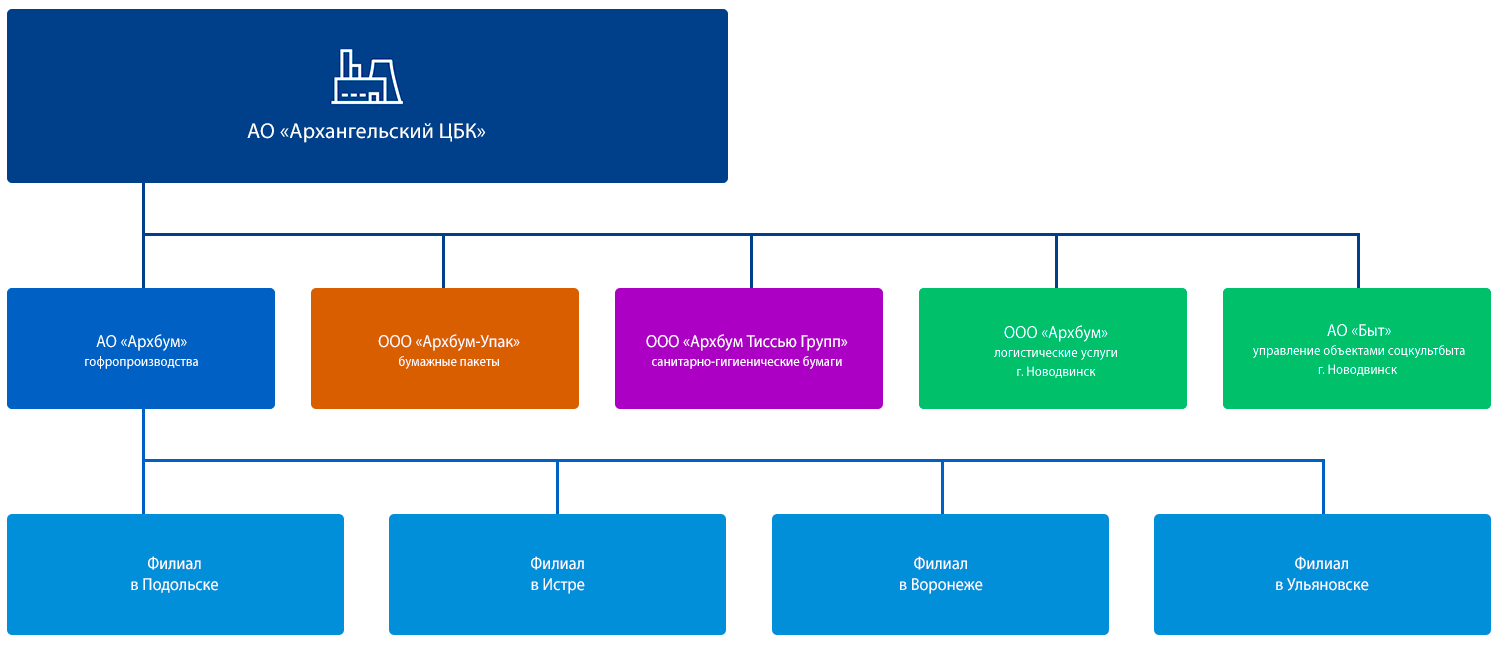

Corporate

management

Arkhangelsk PPM is in the business of manufacturing paper, cardboard, and packaging with production companies in Russia.

Integrated

management system

Today, APPM operates an integrated management system (IMS) that meets the requirements of a number of international standards (ISO 9001, ISO 50001:2018, ISO 14001, ISO 45001). IMS implemented at APPM combines the quality management system, еnergy management system, environmental management system, and health & safety management system.

The fact that the IMS meets the requirements of these standards is proved by the certificates of conformity issued to the Mill by an independent organization. This organization carries out inspection audits of APPM to confirm the validity of the certificates on an annual basis.

The key objective for which APPM has established and developed the IMS is to achieve tangible results in various areas: maximize customers' satisfaction with our products, continuously minimize the Mill's negative environmental impact, minimize any possible health effects for the employees, etc.

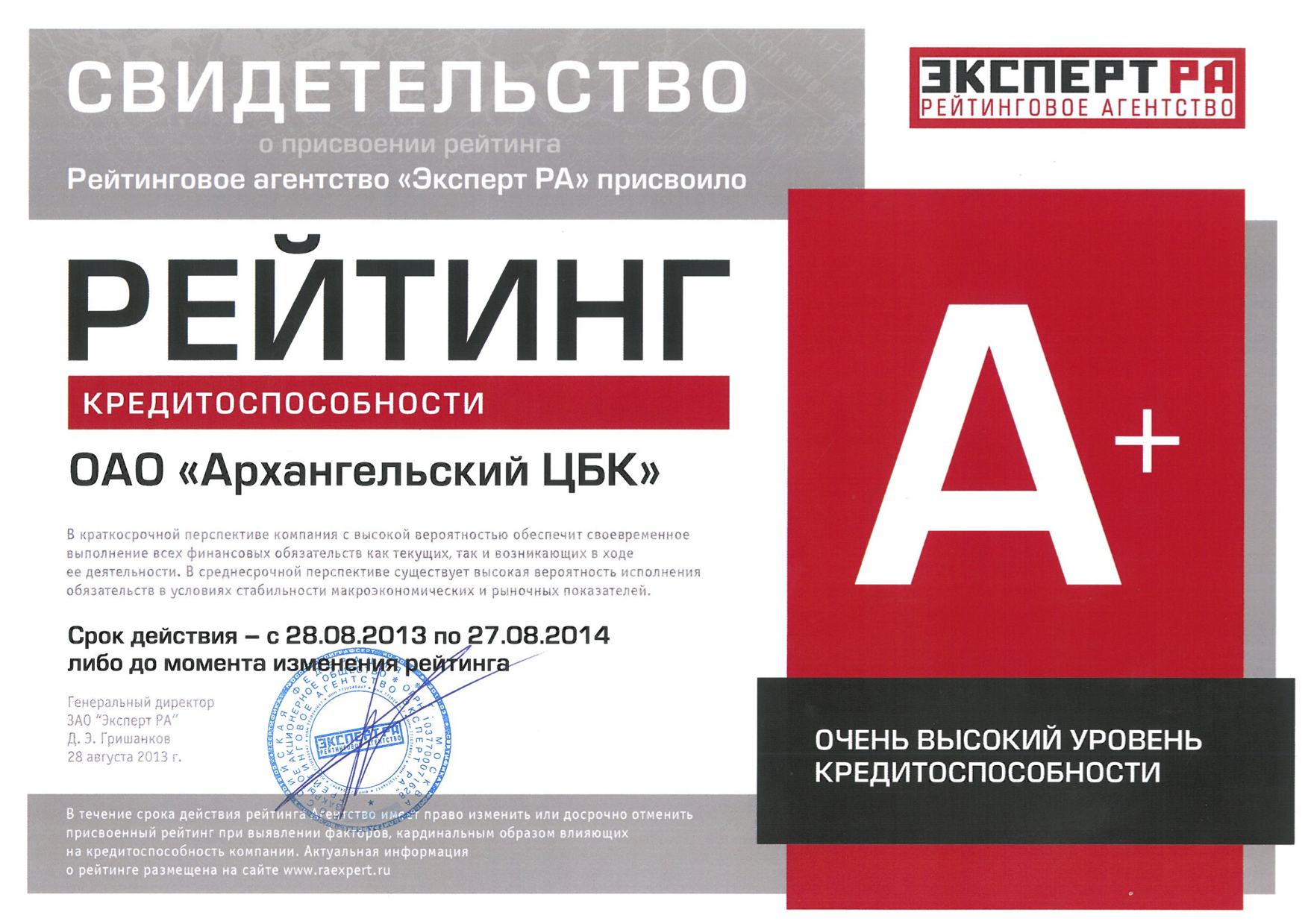

Achievements and awards

Contacts

Arkhangelsk Pulp and Paper Mill Company

Location

164900, Russia, Arkhangelsk region,

Novodvinsk, Melnikov Str., 1

info@appm.ru

Novodvinsk, Melnikov Str., 1

+7 (81852) 6-35-00

Administrative personnel is available from 8:00 to 17:00, lunch break 12:00 to 13:00 Moscow time zone.

Contacts for calls during working hours:

Help Desk

+7 (81852) 6-35-00

General Director's Reception

+7 (81852) 6-32-02

Administrative Director's Reception

+7 (81852) 6-30-62

+7 (81852) 6-32-48 fax

Procurement Director's Reception

+7 (81852) 6-31-82

+7 (81852) 4-23-87 fax

Arkhbum

+7 (81852) 6-34-33 Reception

+7 (81852) 4-65-27 Secretariat

+7 (81852) 4-36-17 fax

arhbum@appm.ru